Landfill diversion.

Reduced greenhouse gasses.

The Bio-CHP™ system enables you to divert organic and plastic waste from open dumps and landfills. Each system can reduce up to 2,200 metric tons of CO₂ equivalent emissions annually by reducing methane emissions released from landfills, offsetting fossil fuel-based power generation, and reducing waste disposal transportation emissions.

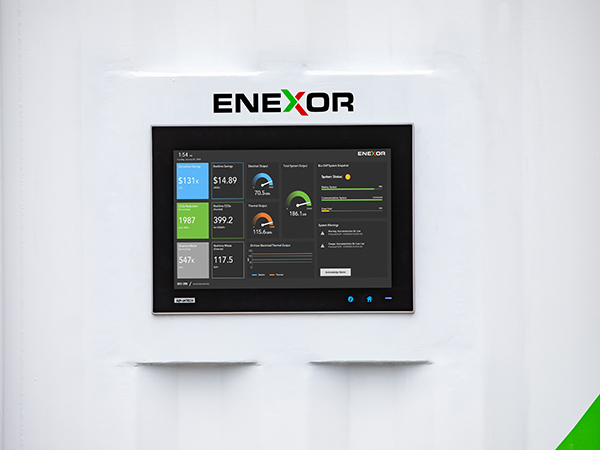

Resilient. Remote monitoring.

Enexor's Bio-CHP™ is designed to operate in the humid and salty environments characteristic of island nations, and resilient enough to withstand hurricane-force winds. The system is equipped with a state-of-the-art controller, which can communicate with IoT enabled devices and supports blockchain technology. Each system is remotely monitored from Enexor's global headquarters in Franklin, Tennessee, ensuring that every unit is always running optimally.

Interactive Bio-CHP™ 360° Tour

Product Features

How It Works

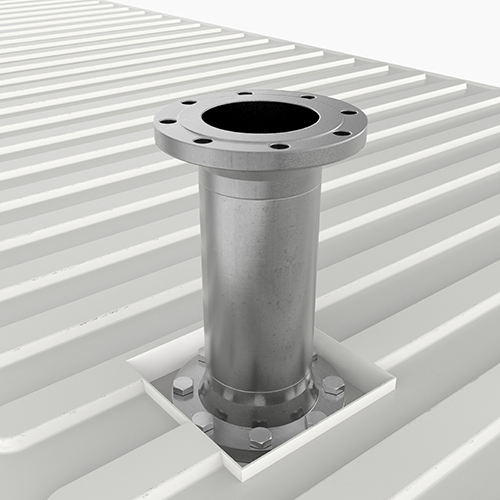

Fuel system feed.

Any combination of organics, plastics or Enex-Fuel™ are inserted into the Bio-CHP™ chute using a speed controlled augured feed system.

Thermal oxidation.

The organics are thermally oxidized in a reactor vessel under a high pressure and high temperatures. These oxidation conditions ensure complete breakdown of the organics, while avoiding the formation of significant thermal NOx compounds typically associated with high temperature fossil fuel combustion.

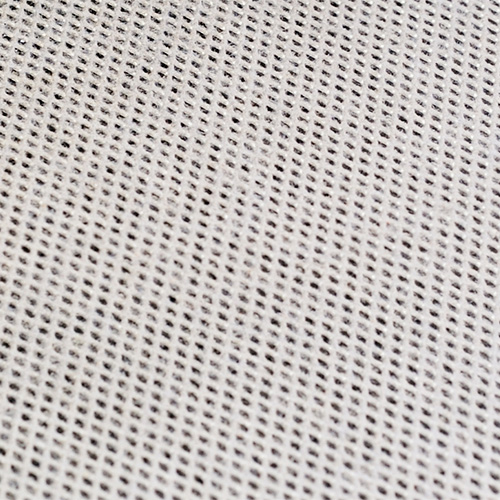

Particulate separation and filtration.

The resulting hot gasses are channeled through a particulate separation system to remove inorganic particulates from the gas stream. These non-hazardous, inorganics are removed pneumatically and stored for future disposal.

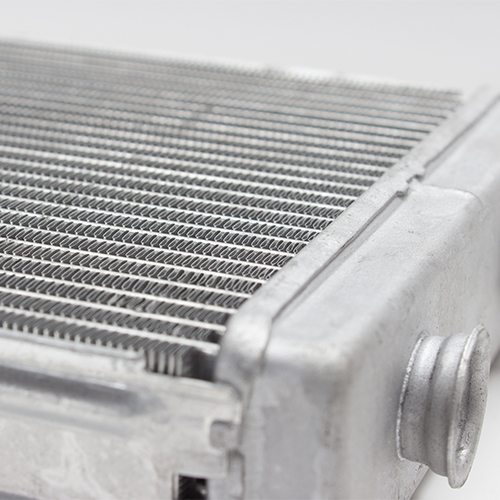

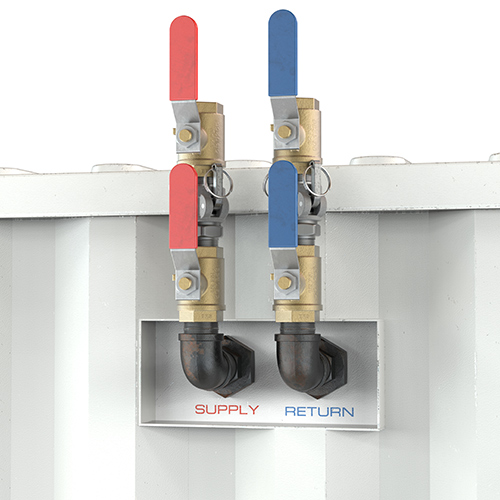

Energy transfer.

The clean, hot exhaust gas stream moves through a high-temperature heat exchanger and heats up pressurized pre-heated ambient air.

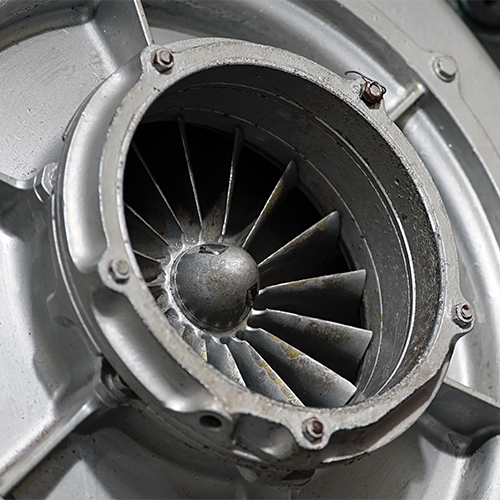

Power generation.

The highly-pressurized air then advances from the heat exchanger into a high-efficiency microturbine to generate power.

Waste heat to thermal energy.

The reduced-temperature combustion exhaust gas passes through a heat exchanger to generate hot water or steam, or route processed heat to an absorption chiller to generate chilled water.

Bio-CHP™ Product Models

;)

Bio-200™

| Fuel: | Enex-Fuel™, organics and plastics |

| Power Rating: | 75 kW |

| CHP Efficiency: | up to 88% |

| Hot Water Output: | 125 kWth (60°C or 80°C) |

| Voltage: | 400-480 VAC |

| Frequency: | 50/60 Hz |

| Interconnect: | UL1741 Certified |

| Dimensions: | 8 ft. (2.43m) x 8.5 ft. (2.59m) x 20 ft, (6.06m) |

;)

PTE-200™

| Fuel: | Plastics |

| Power Rating: | 75 kW |

| CHP Efficiency: | up to 88% |

| Hot Water Output: | 125 kWth (60°C or 80°C) |

| Voltage: | 400-480 VAC |

| Frequency: | 50/60 Hz |

| Interconnect: | UL1741 Certified |

| Dimensions: | 8 ft. (2.43m) x 8.5 ft. (2.59m) x 20 ft, (6.06m) |

;)